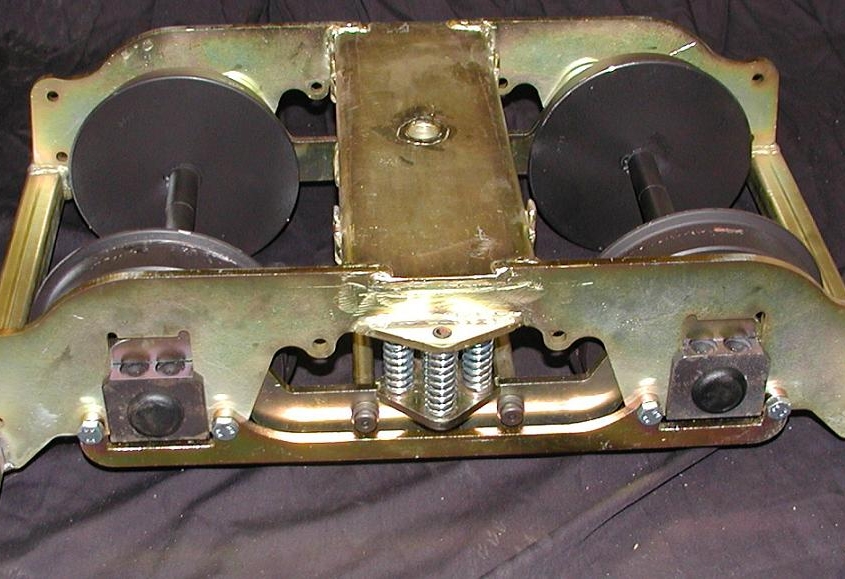

Mk III Bogie

This is basic 7 ¼ in compensated bogie and as position for up to ten compression springs, five on each side. The springs are positioned on the centre line of the bogie and coupe with widely varying loads.

As standard the bogie is supplied with six inch wheels (to the flange) made from EN8 steel to 7 ¼” Gauge Society Specification. Standard metric 6003 sealed ball bearings mounted in sliding bearing block are used.

The side frames, bearing block retainer and bearing support bar are all laser cut from 6 mm mild steel. To maintain accuracy the side frames and folded bolster beam are assembled in a jig before welding.

Two 20 mm square tube sections are added as skid bars to protect the braking mechanism or motor and gear box if fitted. Also supplied is a nylon anti friction bolster plate.

Width = 13″ (330mm)

Length = 20 3/4″ (526mm)

Riding height = 6″ (152mm)

Width of Skid bar = 16″ (406mm)

Wheel centres = 12″ (306mm)

Braking

Three types or braking mechanism can be installed.

Type 1 uses a stainless steel disc and miniature mechanical disc brake caliper assembly with an air cylinder; this can be configured in either fail safe spring on air off principle or air on air off. With a single disc fitted braking is on one axel, to increase the braking to two axels we can supply a toothed belt linking both axle or fit two disc assemblies.

Type 2 is supplied with brake shoes acting on the running surface of the wheel and a standard PNP vacuum cylinder.

Type 3 again uses brake shoes acting on the wheel surface with an air cylinder.

Powered Bogie

The MK III bogie can also be supplied with one or two 500 watt 24 volt DC quad brush motors running on axel mounted worm drive gearboxes with ratios of 7:1, 10:1 and 15:1.

If one motor is fitted we can supply a tooth belt linking both axles giving drive to all four wheels.

The motor and gearbox can be mounted horizontally or vertically and can be fitted with a 24 volt DC fail safe parking brake..

Phoenix Sound Systems Inc.

Phoenix Sound Systems Inc.